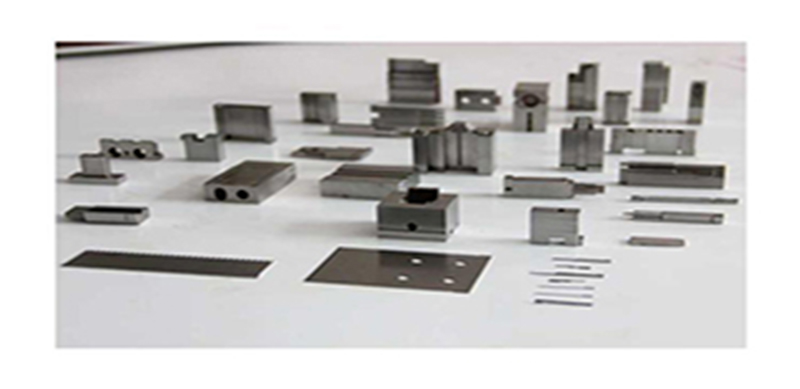

The tools and products used in daily production and life are large to the base and body shell of machine tools, and small to one embryo head screw, button and the shell of various household appliances, which are closely related to the mold. The shape of the mould determines the shape of these products, and the quality and precision of the mold also determine the quality of these products. And the mold processing quality is closely related to its components.

(1) . to discuss the direction of materials (product materials, mold materials).

(2) . gap size of concave and convex die.

(3) . the position and quantity of guide pin are sufficient

(4) . whether the waste rebound is considered and whether the discharging of the die is smooth

(5) . whether monitor and waste rebound sensor are designed.

(6) . the positioning plate and floating pin are selected properly.

(7) . whether the number, size and position of bolts (including unloading bolts) are selected properly.

(8) . consider the punching force and select the punch. The relationship between the dimension accuracy, shape precision and position precision of die parts: when designing machine parts and specifying the machining accuracy of parts, it is necessary to pay attention to the control of shape error within the position tolerance, and the position error shall be less than the dimension tolerance. That is, the shape accuracy of precision parts or important surfaces of parts shall be higher than the position accuracy requirements, and the position accuracy requirements shall be higher than the dimensional accuracy requirements.